WHAT IS TEFRA®

TEFRA® is a family of innovative, ecological hydraulic binders designed for drying and stabilising soil.

Effect on the substrate

- it allows to obtain optimal humidity of the substrate – it dries and stabilises the soil,

- it increases the compressive strength of the soil – it improves soil compaction,

- it increases the load factor of cohesive and non-cohesive soil, it increases its load capacity,

- it increases the resistance of the substrate to water and frost.

Innovativeness

- developed with the scientific community,

- manufactured based on anthropogenic materials,

- formula tailored to the needs of a specific substrate,

- it significantly reduces the time needed to prepare the substrate for further works.

Safety and ecology

- safe for people and the environment,

- it meets European construction standards,

- it does not contain polymers,

- low emission product (Type III Environmental Declaration).

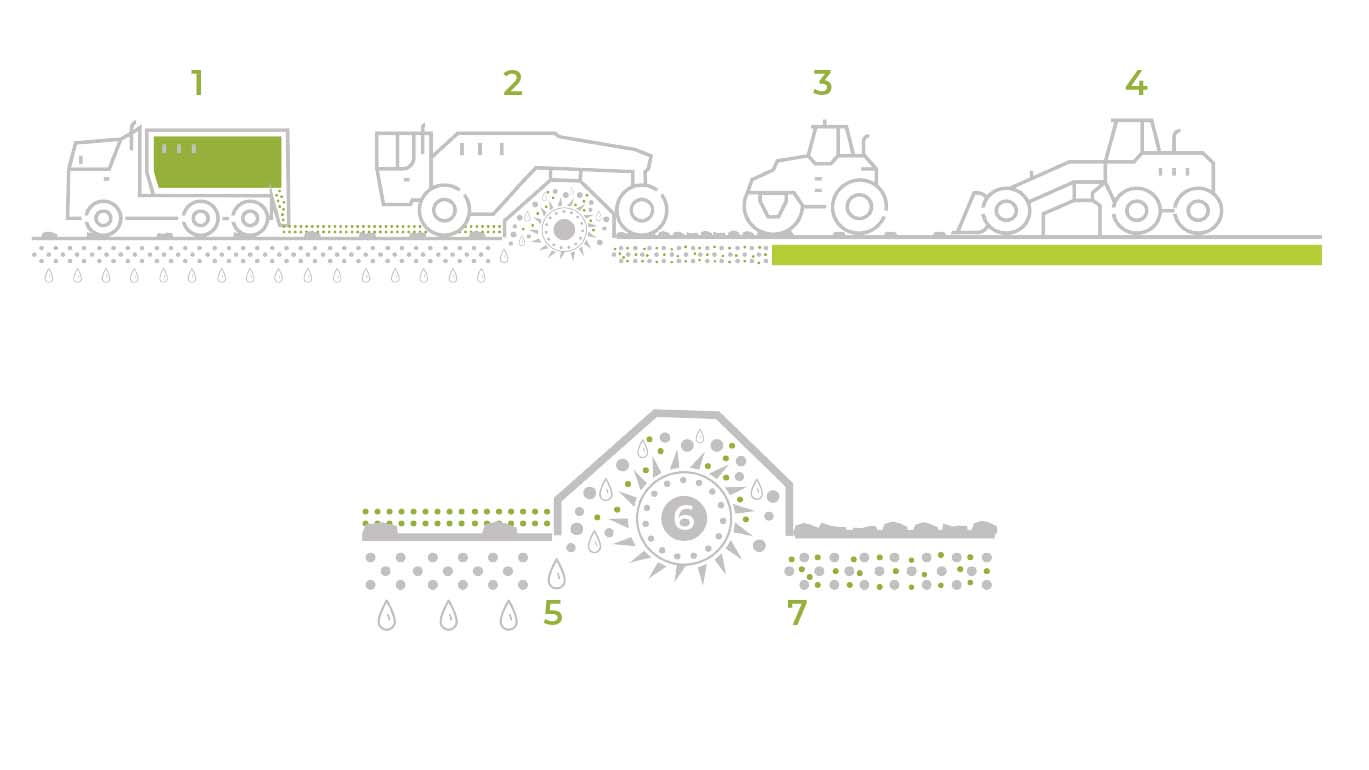

TEFRA® – METHOD OF APPLICATION

TEFRA® is produced locally in the application market and from anthropogenic materials that are available there.

Delivered directly to the construction site – even up to 100 cars sent from one installation per day.

Applied in exactly the same way as traditional loose binders and using the same machines – no additional equipment is required.

Process

1. binder spreader

2. recycler

3. roller

4. grader

5. substrate before amelioration using the TEFRA® binder

6. mixing the substrate with the TEFRA® binder

7. substrate ameliorated with the TEFRA® binder

Effects

Stabilises one layer of the substrate (up to 0.5 m) even within 2 days.

2. recycler

3. roller

4. grader

5. substrate before amelioration using TEFRA® binder

6. mixing the substrate with TEFRA® binder

7. substrate ameliorated with TEFRA® binder

Stabilises one layer of the substrate (up to 0.5 m) even within 2 days.

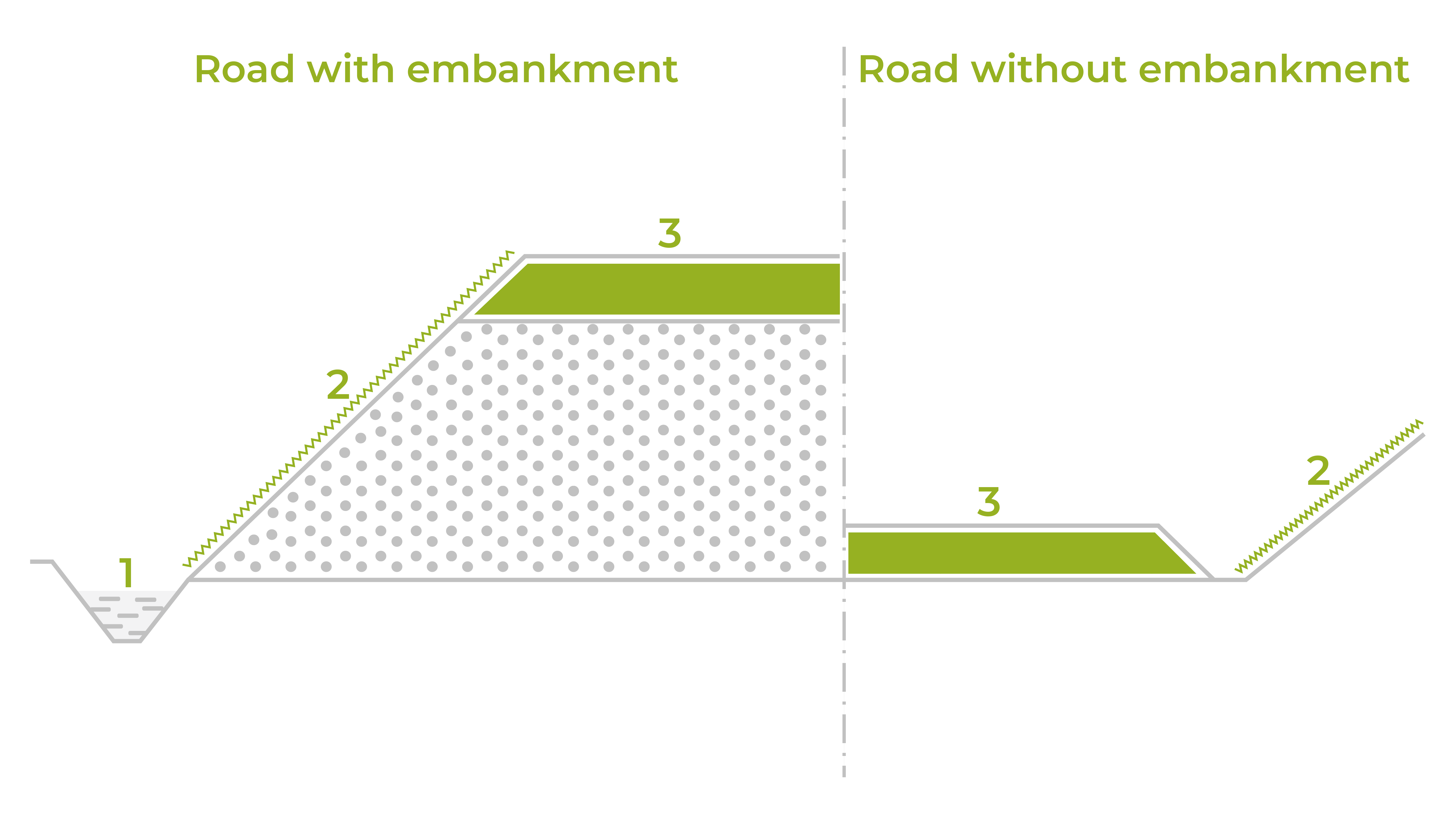

APPLICATION

TEFRA® binders have been successfully used for more than 10 years by leading European construction companies in communication, reclamation, and geotechnical construction.

roads

railroads

bridges

airports

1. water reservoir

2. plant cover

3. substrate ameliorated with TEFRA®

TEFRA®25

Useful for meliorating and modifying mainly fine-grained soil in transport construction.

TEFRA®35

It ameliorates soils requiring a higher load-bearing capacity in transport and large-area construction.

BENEFITS

LOW COSTS

Competitive prices in relation to traditionally used materials for drying and stabilising soil

SAVES TIME

The application of TEFRA® significantly reduces the time needed to prepare the substrate for the construction of the investment, even 2 days are enough to stabilise the soil (layer up to 0.5 m)

EASY APPLICATION

TEFRA® is applied in the same way as traditional loose binders, using the same machines

DIRECTLY TO THE CONSTRUCTION SITE

The binder is delivered exactly when needed, without having to store it on site

EFFICIENT TECHNOLOGY

Up to 100 binder cars from one installation per day, up to 200 000 tonnes per year!

DEDICATED FORMULA

The proportions of individual components of the mixture are adjusted to the needs of the specific investment

IN LINE WITH SUSTAINABLE DEVELOPMENT

The proprietary technology, following the idea of a circular economy, allows the transformation of materials commonly considered as waste into a fully-fledged and safe product

ENVIRONMENTALLY FRIENDLY

A formula that is safe for people and the environment, certified carbon efficiency; it contributes to reducing the carbon footprint of the country’s economy; can be the subject of international climate change financing mechanisms

TRUST AND PROVEN EFFECTIVENESS

More than 2 million tonnes of TEFRA® have already been used in large road and highway construction projects in Poland.

TEFRA® has all the necessary certificates confirming compliance with the technical and environmental standards applicable to road construction in the EU.

Global potential – in cooperation with the Ministry of Public Works and Human Settlements, a laboratory test of the binder and local soil has also been carried out at the Research and Development Centre for Roads and Bridges in Indonesia. It confirmed the excellent performance and properties of the substrate after using TEFRA®.

The more TEFRA® is used

t

the more CO2 emissions are avoided

t CO2e

The more TEFRA® is used

(t)

the more CO2 emissions are avoided

(t CO2e)

1 tonne of TEFRA® used is about 0.9 tonnes of avoided CO2e emissions.

The use of the TEFRA® binder instead of traditional materials for stabilising and drying the substrate contributes to reducing the carbon footprint of a given construction investment.

Case studies

selected implementations

In less than ten years, the TEFRA® technology has changed the Polish soil stabilisation market, resulting in a move from cement to TEFRA®.

Currently, 85% of roads in Poland are stabilised with TEFRA®

Before 2010, most of the stabilisation was done with cement

800 km of express roads and freeways commissioned and under construction using TEFRA® (by 2018)

Construction of the S-7 expressway on the Kalsk-Milomłyn section

Quantity of supplied material: 114 thousand tonnes. The contractor for this expressway was Strabag. By using the TEFRA® binder, the contractor has achieved the required load-bearing capacity of the ameliorated subsoil – 40 MPa.

Construction of a chipboard factory in Biskupiec

Quantity of supplied material: 77 thousand tonnes. The investment was commissioned by Egger Biskupiec sp. z o.o. The required load-bearing capacity of the improved substrate and embankment layers was achieved by using the TEFRA®25 binder.

Construction of the Pomeranian Metropolitan Railway in Gdańsk

Quantity of supplied material: 42 thousand tonnes. The contractor for the railroad line was Budimex. By using theTEFRA®binder, the contractor has achieved the required load-bearing capacity of more than 80 MPa, at a significant cost reduction.

Reconstruction of the Goleniów Airport

Quantity of supplied material: 3 thousand tonnes. The contractor for the construction was Budimex. By using the TEFRA® binder, the contractor has achieved the required compressive strength of Rm 2.5 MPa in non-cohesive soils.

EKOTECH Group

Gen. Stanisława Skalskiego 1 / U16

03-982 Warsaw, Poland

tel. +48 22 587 58 39

fax. +48 22 698 14 20

mail: biuro@ekotechtrade.eu

www.ekotech.pl